-

1.What is the difference between PVC and PET?

PVC (Polyvinyl Chloride): Polyvinyl chloride, often with plasticizers and stabilizers to adjust its flexibility. PET (Polyethylene Terephthalate): Polyethylene terephthalate, a polyester polymer. 1.Environmental performance: PVC contains chlorine, which will produce harmful gases (HCl) when burned. Some plasticizers are not environmentally friendly. However, PET does not contain chlorine, is environmentally friendly and recyclable, and is more in line with international environmental protection trends. 2. Hardness: PVC is relatively soft and flexible, with a scratch resistance rating of 1H. PET is harder, has strong stiffness, is not easily deformed, and has a scratch resistance rating of 3-4H. 3.Heat resistance: PVC has poor heat resistance and deforms at about 60-80℃, while PET has better heat resistance and can withstand about 150℃. 4. Cost: PVC raw materials are cheaper and easier to process, while PET raw materials and processing costs are higher. 5. Printing/coating properties: PVC is easy to process and color, and is suitable for low-end decorative films. PET has high surface tension and requires corona/coating treatment, but the finished product is more refined.

-

2.What is the difference between PET and PETG?

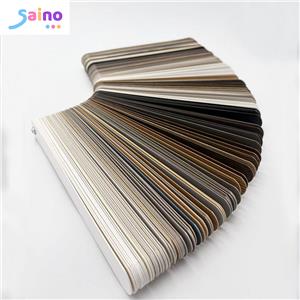

PET (Polyethylene Terephthalate) Polyethylene terephthalate (PETG) is a crystalline polyester. PETG (Polyethylene Terephthalate Glycol-modified) PETG is modified by adding ethylene glycol to prevent partial crystallization, making it softer and easier to process. 1. Environmental performance: PET and PETG are both recyclable and environmentally friendly new materials. 2. Production process: Our PET is BOPET, which adopts the production process of biaxial stretching, while PETG is extruded and then coated, so PET has better scratch resistance. 3. Our PET is BOPET. PET is stretched longitudinally and transversely during the production process, and its scratch resistance is slightly better than PETG. PETG is longitudinally stretched and extruded before coating. PETG adopts a three-layer GAG structure, so the color difference can be better controlled. 4. Applications: Our PET is usually converted into transparent film with a hardness of 3-4H, and PETG is converted into colored film. The color difference control rate between different batches can reach ΔE<1, with almost no color difference.

-

3.What services can SAINO provide for you?

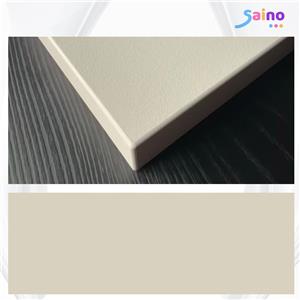

Foshan Saino New Materials Co., Ltd., since its founding in 2010, has been committed to the in-depth development of polymer polyester film (PET Film). Bolstered by a mature and stable production system, a precise and efficient color-matching technology, and a professional and rigorous quality inspection team, Saino’s products have earned an excellent reputation and widespread market recognition in the cooperative industries of furniture, decoration, and construction. Adhering to the philosophy of "outlining the beauty of life with colors", Saino takes PET film as the innovative foundation and has established an independently controllable color-matching system. By skillfully integrating the film with wood, it infuses architectural spaces and home environments with rich colors and elegant textures, enabling every detail to convey the inherent beauty of life. Saino has always operated under the orientation of "providing solutions for customers". Thanks to its strong R&D capabilities and efficient team collaboration, it offers customers customized one-stop services including color matching, surface treatment, logo customization, and edge band color coordination. Moreover, through collaboration with multiple partners in the industrial chain, the company has further expanded its service scope, providing customers with supporting services such as the supply of upstream and downstream auxiliary products and post-stage freight transportation, thus building a closed-loop service system from front-end customization to back-end support.