PET Solid Color Rough Film

Brand SAINO

Product origin China

Delivery time 3-21 Days

Supply capacity 500,000-600,000 meters/month

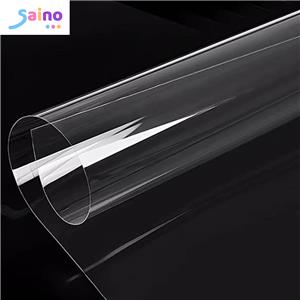

1. Texture solid color PET film is based on PET or PETG, with mechanical embossing on the surface to form a film with tactile feel and visual depth.

2. Anti-fingerprint PET film supports matte, anti-scratch, anti-fingerprint and other post-processing processes.

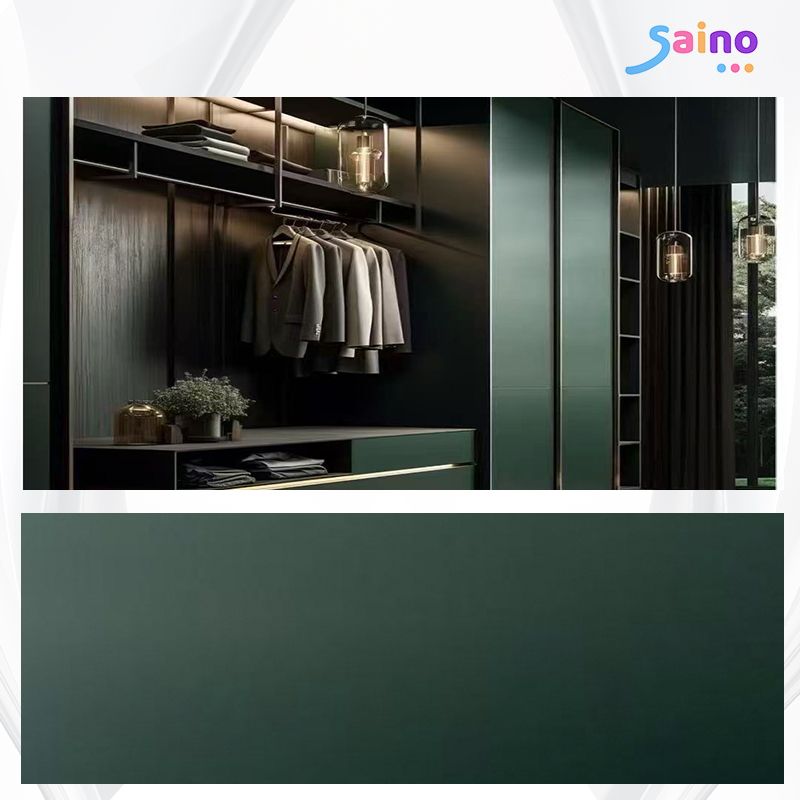

3. Scratch resistant PET film is mostly used in doors, cabinets, storefronts, office partitions, etc. to improve durability and visual level.

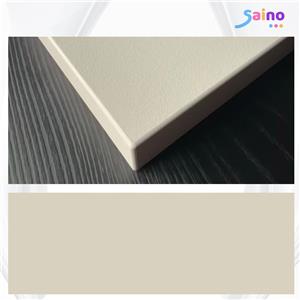

4. PET Solid Color Rough Film uses a pure color ultra-matte + subtle texture or sandy treatment, which is scratch-resistant, anti-fingerprint, and easy to clean.

About PET Solid Color Rough Film

Composition & Structure

| Layer | Material | Thickness(mm) | Total Thickness(mm) |

| I | PETG Film | 0.12-0.27 |

0.15-0.3 |

| II | Adhesive Layer | 0.007 | |

| III | PE Protective Film | 0.03 |

[Length]: 200-350m per roll.

[Material]: Polyethylene Terephthalate.

Key Features

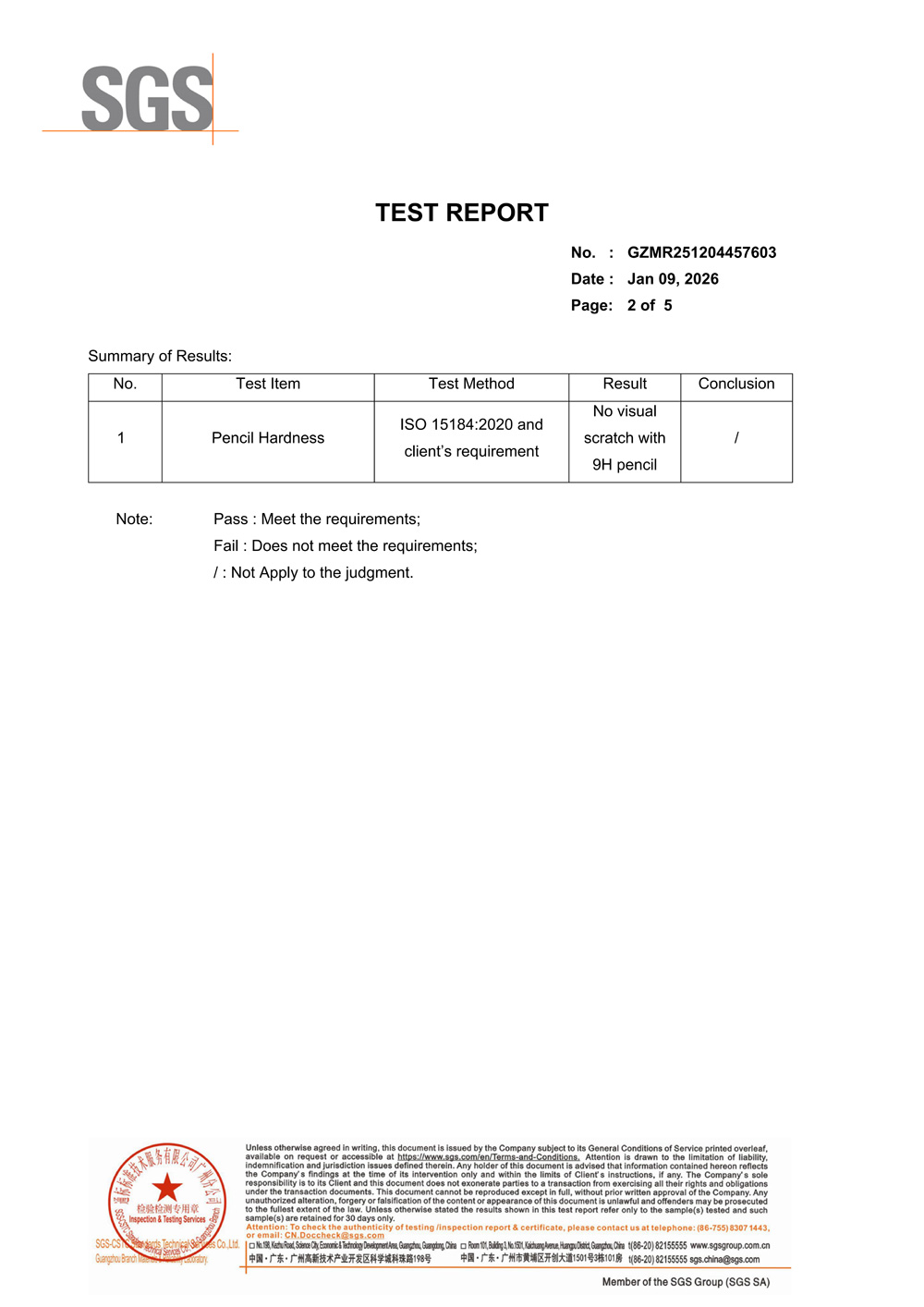

Excellent scratch resistance

After formulation, extrusion, and precision mold coating, the PET Solid Color Rough Film passes through a rubber embossing roller, creating a fine, sand-like ("frosted"/approximately 60-120 mesh) micro-texture on its surface.

This micro-texture of the PET Solid Color Rough Film can trap tiny abrasive particles while reducing the actual contact area between scratching objects and the film, thereby significantly improving scratch and abrasion resistance.

At the same time, the surface of the PET Solid Color Rough Film is coated with a hardening layer—typically a UV-cured or heat-cured acrylate or melamine-silica composite—giving it a surface hardness of 4H-5H (pencil hardness scale), further enhancing the abrasion and chemical resistance of the PET Solid Color Rough Film.

Excellent anti-fingerprint properties

The anti-fingerprint PET film utilizes a "sandblasting" surface treatment process. The physical structure of the anti-fingerprint PET film creates a uniform roughness at the microscopic level, resulting in a smooth but non-reflective surface. This sandblasted texture reduces the direct contact area between fingers and the smooth surface.

Therefore, even with frequent touching, human sebum and dirt are less likely to adhere to the surface, making Anti-fingerprint PET film difficult for fingerprints to remain on the anti-fingerprint PET film. Even if a small number of fingerprints are left, Anti-fingerprint PET film will be very faint and easily dissipate.

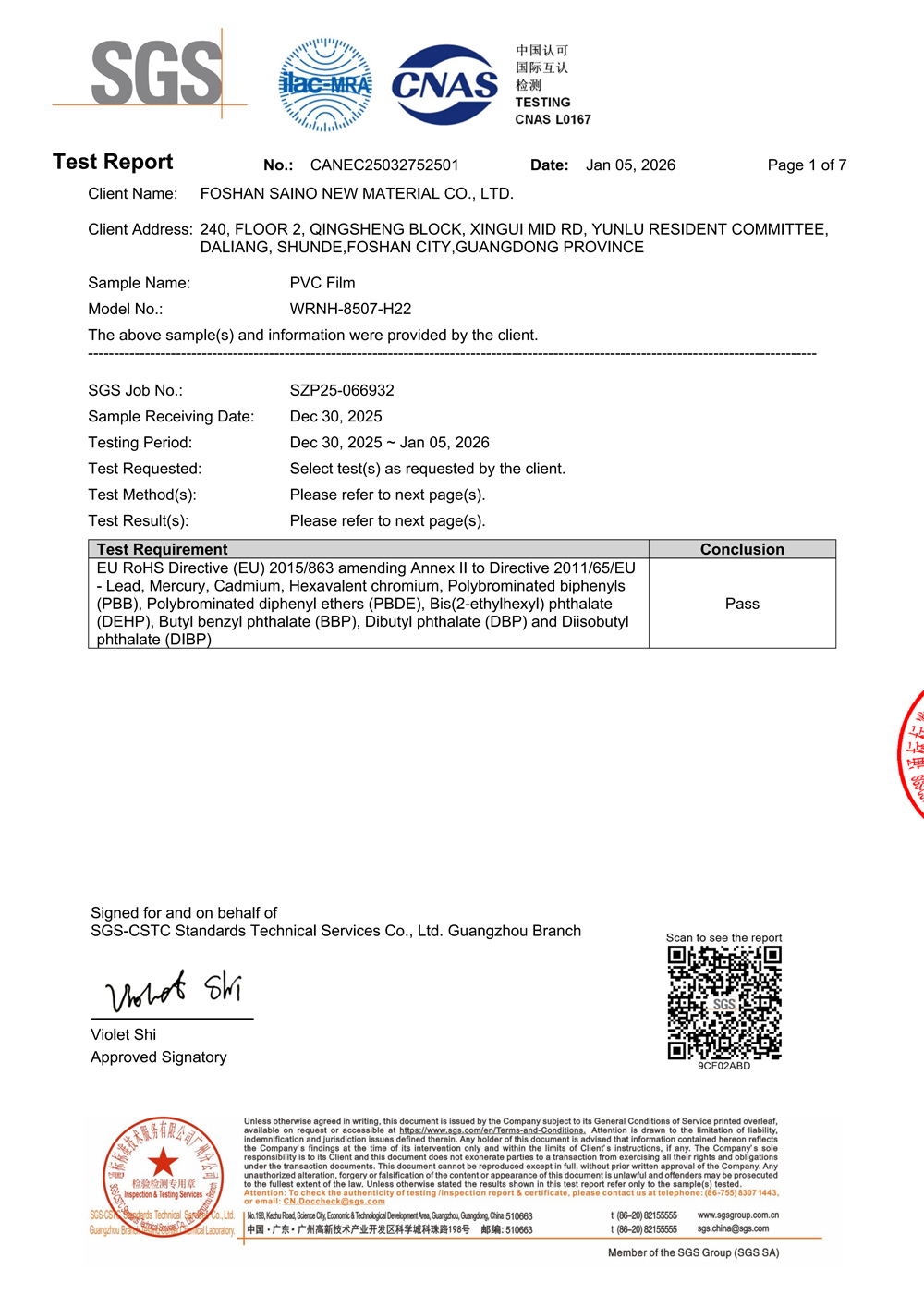

Environmental protection and safety

Compared to PVC and melamine-based laminates: Scratch resistant PET film is safer and easier to recycle.

Chlorine and phthalate-free: PET is a chemically stable polyester. Scratch resistant PET film does not contain plasticizers such as DEHP/DINP and does not easily generate dioxins.

Low VOC emissions = cleaner indoor air

VOC-free lamination solutions: High-quality Scratch resistant PET film is typically laminated using water-based adhesives, UV or EB coatings, all of which comply with CARB Phase 3, REACH, and GreenGuard standards. Scratch resistant PET film has 40%–60% lower VOC emissions than solvent-based adhesive PVC or melamine-based laminates.

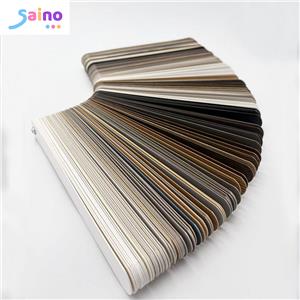

Frosted texture

Thanks to a special micro-embossing process (such as embossing or roller texturing), Texture solid color PET film visually presents a low-gloss, high-haze effect (glossiness of approximately 1-4%, haze ≥90%), creating a granular, layered texture. In terms of touch, it is neither smooth nor soft. Texture solid color PET film offers a raw yet refined tactile experience, reminiscent of the texture of naturally weathered minerals, both rugged and delicate.

The surface texture of Texture solid color PET film is similar to natural sandstone, featuring a highly dense embossed pattern (10-25 micrometers) with irregular orientation. As light and shadow shift, Texture solid color PET film creates a weathered, ever-changing textural effect.

Application scenarios:

Our advantage

Global Services

Professional services delivered across multiple countries and regions

Flexible MOQ

Reasonably reduce production startup costs for customers

24-hour service

Operating around the clock—24/7/365

Fast shipping

Ensure quality while sending goods as quickly as possible

About Us

Foshan Saino New Materials Co., Ltd., since its founding in 2008, has been committed to the in-depth development of polymer polyester film (PET Film). Bolstered by a mature and stable production system, a precise and efficient color-matching technology, and a professional and rigorous quality inspection team, Saino’s products have earned an excellent reputation and widespread market recognition in the cooperative industries of furniture, decoration, and construction.

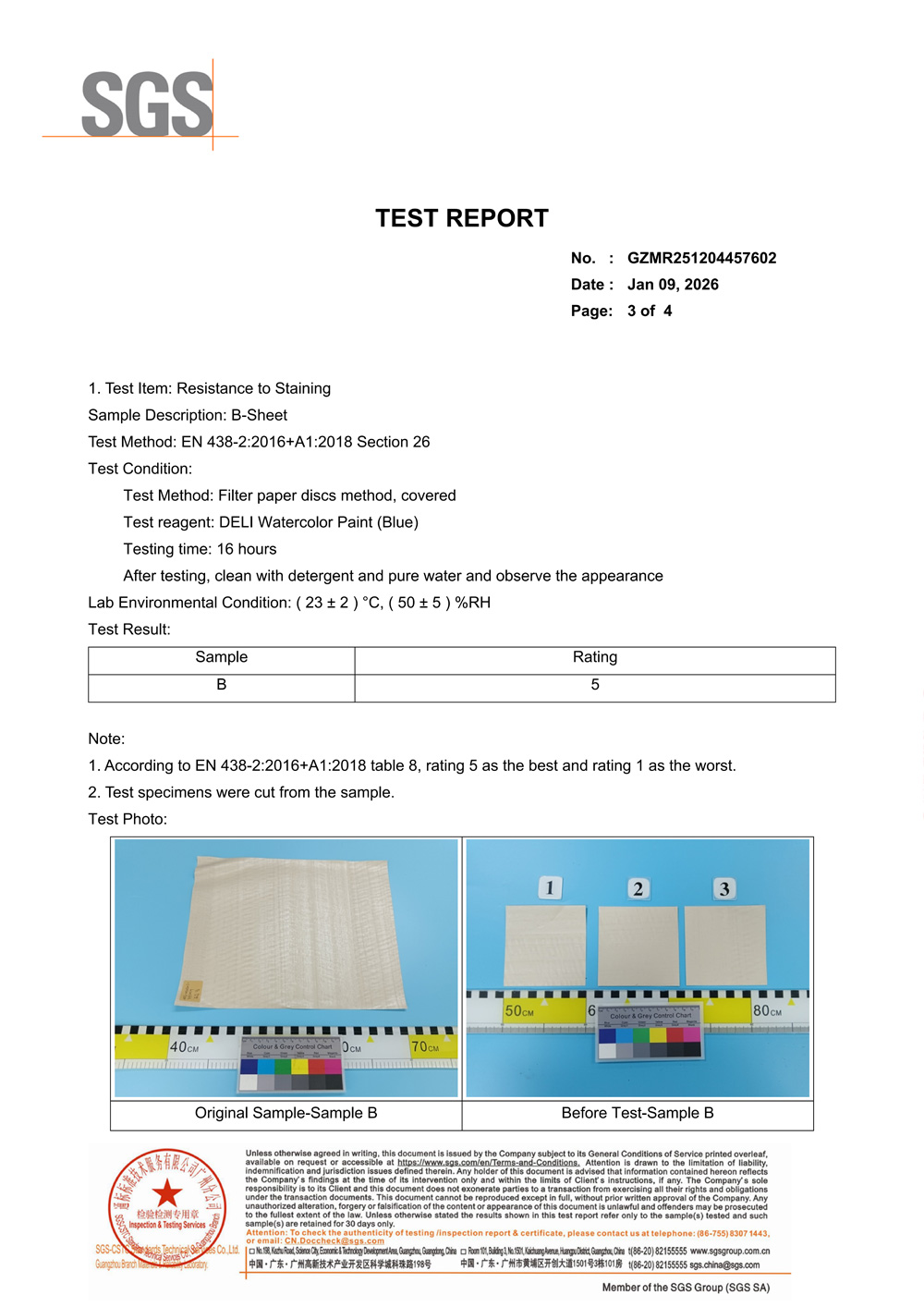

Certifications

Our Factory