ABS vs. PVC Edge Banding: Which Material is Best for Your Project?

ABS vs. PVC Edge Banding: Which Material is Best for Your Project?

Choosing the right edge banding material is critical for enhancing furniture durability, aesthetics, and lifespan. Among the top contenders, ABS Edge Banding (Acrylonitrile Butadiene Styrene) and PVC Edge Banding(Polyvinyl Chloride) each offer unique advantages, making the decision dependent on your project’s priorities.

1. Material Composition and Properties

ABS edge banding consists of acrylonitrile (for chemical resistance), butadiene (for flexibility), and styrene (for rigidity). It is highly impact resistant and heat tolerant, making it suitable for edge banding applications in high-traffic areas. Meanwhile, PVC edge banding is known for its versatility.

It has better fire resistance and added flexibility, which allows it to stick to almost any curve or corner, including unfinished edges of furniture. Both edge bandings also differ in temperature resistance. Although ABS withstands higher temperatures, PVC is more resistant to weather conditions and moisture, making it more suitable for outdoor applications and areas exposed to moisture.

2. Aesthetic and Design Flexibility

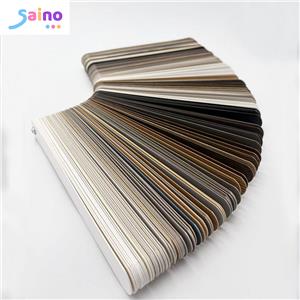

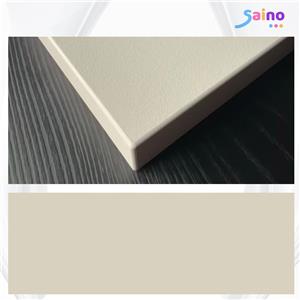

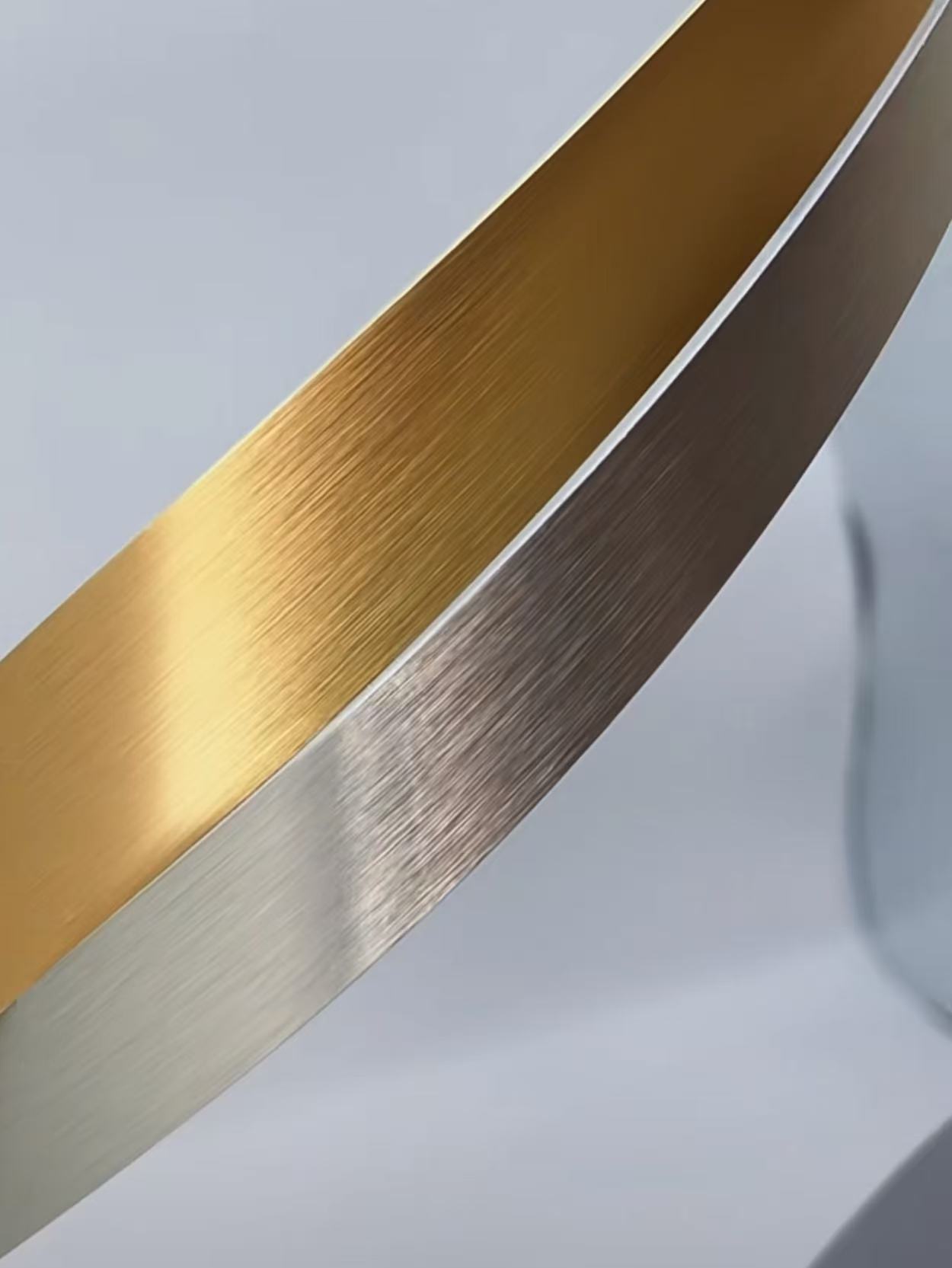

The features of ABS edge banding include a silky, matte surface that retains color well, making it ideal for contemporary simple styles. The rigidity of ABS creates sharp edges for defined patterns. PVC edge banding differs as it can come in multiple styles such as glossy, matte, and even textured to resemble wood, marble, or metal. PVC can flex and bend to create more complex patterns and designs. Advanced surface treatment technology can also replicate textures.

3. Durability and Performance

ABS edge banding is also known for its impact resistance as it can withstand the bumps in a busy office or kitchen. PVC edge banding is more resistant to scratches, and the coatings that are applied and are to PVC keep the surface smooth. ABS edge banding is better for heat resistance, but fades in color due to prolonged exposure to the sun. PVC edge banding does not fade from the sun and will withstand moisture. This makes it ideal for use in bathrooms, kitchens, and outdoor furniture.

4. Eco-Friendliness

ABS edge banding is made from petroleum and its production is energy excessive, and the production lacks proper recycling. PVC edge banding uses modern eco-friendly methods and incorporates used water-based inks, eliminating the harmful plasticizers and in turn, lowering the overall VOCs and toxins. It can be noted that the traditional vinyl edge banding did indeed have an impact on the environment but with the new water-based films, it can now be considered the better alternative.

5. Cost Considerations

For large projects or budgets, PVC edge banding is a perfect option because it is inexpensive. ABS edge banding costs more initially, but it is more economical over time because it requires less maintenance and less frequent replacement in high-wear areas.

Conclusion

Select ABS edge banding when you need impact resistance, heat tolerance, and durability for heavy-use environments. Choose PVC edge banding when you need design flexibility, resistance to moisture, and lower costs. Considering durability, design, and budget will guide you to the material that suits your project best.