What Equipment is Required for PUR/PETG Decorative Film Applications?

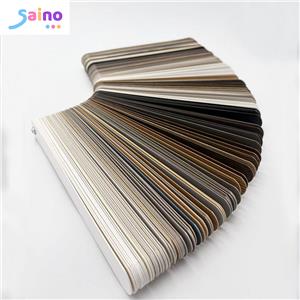

Hey everyone! I'm PET film, and this is my good partner, PETG film. We're becoming increasingly popular in the furniture and architectural decoration industry! Everyone praises our high-quality appearance and eco-friendliness, calling us the "perfect successors" to traditional surface materials.

However, to truly shine and show our best, we can't do it alone. That's where a behind-the-scenes expert comes in – the PUR flat lamination machine. Industry experts say that the three of us together form the "golden triangle" of modern surface finishing technology!

Why does it have to be a PUR flat lamination machine?

This has to do with the "quirks" of me and my PETG sister. I (PET) have a relatively "tough" personality, but my toughness is slightly weaker. My PETG sister is more "flexible" and particularly good at thermoforming. But no matter which of us it is, to firmly "stick" to various boards (such as MDF and aluminum panels) without separation or bubbling, we need a very precise and professional "bonding" process.

Those traditional methods or simple equipment just can't handle us:

• Uneven glue application? – We'll get angry and bubble up, making our surface look like orange peel!

• Uncontrolled pressure? – Too little pressure won't bond us properly, and too much will deform us.

• Incorrect temperature? – The special PUR adhesive is a "temperature control freak," and it won't work if it's too cold or too hot.

• Unclean environment? – Our surface is smooth as a mirror, and we hate dust particles interfering.

That's where the PUR flat lamination machine, this "all-around manager," shines! It has incredible capabilities:

1. "Millimeter-level" glue application: Its glue application system is incredibly precise, ensuring the glue is applied evenly like a thin veil, with minimal error, fundamentally eliminating bubbles and glue leakage.

2. "Constant temperature" guardian: The built-in intelligent temperature control system provides the most suitable temperature environment for the PUR adhesive, ensuring it's always at its best.

3. The "Intelligent" Pressure Master: Equipped with a combination of hot and cold pressure rollers, it applies just the right amount of pressure according to different situations, ensuring a tight bond without wrinkles.

4. The "Ultimate" Cleanliness Enthusiast: It features a multi-stage dust removal and purification system, cleaning the surface of the panels to perfection, meeting our high standards for a clean bonding environment.

Of course, this "butler" also flexibly adjusts its strategy to suit our different personalities:

• For me (PET film), it's gentler, avoiding large temperature differences during preheating to prevent shrinkage, and applying pressure gradually, finally giving me ample time to cool and solidify.

• For my PETG sister, it carefully controls the temperature to prevent excessive heat shrinkage, maintaining even tension during unwinding and giving her more time to solidify and stabilize her properties.

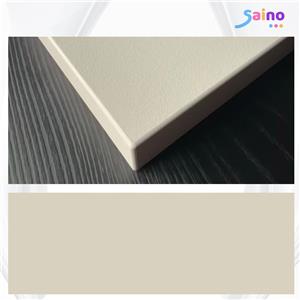

Real-world case study: A cabinet manufacturer's turnaround

Previously, a cabinet manufacturer wanted to use my high-gloss version for their door panels, but their equipment was rudimentary, resulting in a very low yield rate. I always had orange peel texture, and the edges tended to curl. That is, until they brought in the PUR flat lamination machine, this "great butler"! Through a series of precise dust removal, accurate adhesive application, and segmented pressure control, my appearance finally shone perfectly – the surface was smooth as a mirror, the yield rate soared, and customers were full of praise.

Together, we will shine in the future!

Now, the market for our PET family is growing, and the demand for high-quality, environmentally friendly decoration is also increasing. Therefore, the future prospects of the PUR flat lamination machine, this crucial partner, are very bright. Choosing it is not only a smart decision for manufacturers to enhance product competitiveness, but also a strategic choice to embrace a green and intelligent future.

So, our "golden triangle" combination is not just a simple encounter, but a destiny to lead the industry towards a higher quality, more environmentally friendly, and more exciting future!