Why is UV Inert Coating Film so popular?

Technological innovation in surface protection – dry cleaning cloths for building materials refers to a new publication from Ecovative Design that describes how the company has developed a novel type of thin film that protects stone or equals against weathering by sunlight (ultraviolet radiation).

UV inert coating film have been demonstrated to be good building material with broad prospects for application due to its good weather resistance, self-cleaning properties and environmentally friendly features. Based on an innovative introduction of coating technology, the new way offers greener and more powerful surface treatment solution for building materials industry, which is believed to carry forward high performance and long lifespan in this field.

The Technical Properties and Applicability to Building Materials

The primary benefit of UV Inert Coating Film is that its “inert” feature allows it to react with less sources like pollutions, acid rain and ultraviolet rays ,replacing all holing conventional hydrophobic chemical coatings significantly lower concentration ≤ 10%. This characteristic is Tailored to meet the high specifications of weather and corrosion resistance in building materials industry.

It could ensure surface gloss remain long time&color stability when building curtain wall application. Higher construction efficiency, compared with traditional fluorocarbon coatings, UV Inert Coating Film UV curing several seconds away to solve the problem of solvent evaporation and meet green building standards. The door and window profile surface coating with UV Inert Coating Film has a very good wear resistance, self-cleaning performance. Because it has a low surface energy, there will be no need of high frequent cleaning process as the dust and stains can not attach on its raining-wash clean exterior any more. Meanwhile, the UV Inert coating film is flexible enough that it will not crack or pill up while going through processing of bending and cutting profile.

Application Scenarios and Performance

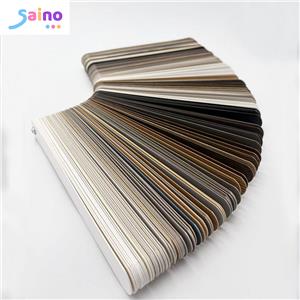

At present, UV Inert Coating Film is mainly used in the building materials industry for aluminum curtain wall boards, door and window profiles this three areas. UV Inert Coating Film is a unique type of surface coating that can be applied to the aluminum panel surface in curtain wall applications by roller coating or spraying and forms a protective layer after UV curing.

Test result shows, UV Inert Coating Film performs more than 3000 hours salt spray resistance and controls coloration within the scope of standard for over 4000hours artificial ageing test which is superior to traditional coatings.

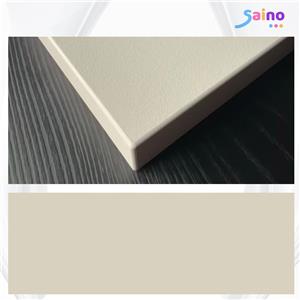

Its applications in the interior decoration field include: for applying UV Inert Coating Film to substrates such as fireproof board, gypsum board and MDF boards with properties of stain resistance resistant, scratch-resistant anti-pestle easy cleaning (scrub).

In particular for use on the surface of public places with relatively high requirements for hygienic properties, UV Inert Coating Film is beneficial which will bring greater advantages in respect to antibacterial and easy-to-clean functions- namely hospitals; schools or shopping malls. In a hospital renovation demonstration, 6 months after the application of UV Inert Coating Film on wall panels there was a >60% reduction in surface bacterial adhesion and 40%-100% greater efficient cleaning.

Technological Advantages and Production Efficiency

The technology of UV Inert Coating Film also allows its wider promotion in the building material industry. One of the most important reasons is its high production efficiency, and UV curing speed can reach 10-20 m/min when using a single-side induction oven; moreover, it takes no more than one day to process over 5000 square meters in general with only one product line which far exceed traditional thermosetting.

Also, it has good environmental performance; UV curing process no solvent evaporation, almost zero VOC emissions to meet national environmental protection policy requirements. Third, energy saving: the LED-UV curing system is only 30% as hot as a traditional thermosetting device and does not require a heating/cooling time to quickly start the equipment.

UV Inert Coating Film can be in line with the substrate pretreatment, coating, curing and winding continuous production line automation is high labor cost. Another building materials company, reducing 15% of overall costs and raising the grade more than 98%% when establishing an UV Inert Coating Film production line.

UV Inert Coating Film Technical Challenges and Solutions

UV Inert Coating Film has advantages, but its promotion situation in building materials industry which are greatly potential remains to be challenge. Substrate adaptability: Different building materials (aluminum, steel, wood and plastic components) have very different surface properties that need to be treated with targeted primer technologies.

At present, by changing the composition of UV Inert Coating Film formulators to increase adhesion enhancers for most substrates. Outdoor weather resistance verification: The building material needs to be used continuously for outdoor exposure and the performance need verifying through accelerated aging tests and real practical case studies. At this stage, the UV Inert Coating Film has passed a series of international standard tests and been successfully used in many projects for 5 years or more.

Third, there is the dumb question of money. Even as they may be more costly than typical coatings, the total life-cycle cost of UV Inert Coating Film based materials is much better when taking into account production efficiency, the environmental consequences and product lifespan. This could mean further reduction in costs as large orders are placed and the materials for these bikes advance.

Industry Prospects and Policy Support

UV INERT COATING FILM is believed to be one of the key applications in building materials industry by industry experts. With the rise of green buildings and prefabricated houses, there are higher requirements for surface performance and environmental protection properties of building materials, which also highlights the technical advantages of UV Inert Coating Film.

It is expected that over the next 3 years, penetration of UV Inert Coating Film in Building Curtain Wall will rise from current levels of 5% to well above 15%.

It is clear and explicit at the policy level; in requirements like Green Building Evaluation Standard, General Specification for Building Energy Conservation and Renewable Energy Utilization…

Consequently, UV Inert Coating Film| as a low-VOCs、high-performance coating technology is in line with this policy direction. At the same time, industry standard development is in progress to technically support standardized UV Inert Coating Film application.

In summary, UV Inert Coating Film as a rising star of surface treatment technologies in the building materials industry has been highly recognized with its outstanding properties, high efficiency processes and environmental friendly features. With the continuous maturity of technology, the optimization of costs and the accumulation in applications experience, this technology is expected to become an important choice for building materials surface treatment by leading industries towards high-quality as well-sustainability.