Why is PETG membrane the most suitable material for PUR flat lamination?

PETG Film and PUR Flat Lamination: A Perfect Match – A Combination of High Transparency, High Adhesion, and High Stability

In the decorative materials industry, the compatibility between materials and processes directly impacts the performance of the final product. The combination of PETG film and PUR flat lamination has proven highly effective in the high-end decorative market, becoming a favorite in industries such as furniture, building materials, and advertising signage due to the deep synergy between their material properties and process advantages.

This combination not only solves many pain points in the flat lamination process of traditional materials but also demonstrates significant advantages in environmental friendliness and durability.

Material Properties Determine Process Compatibility

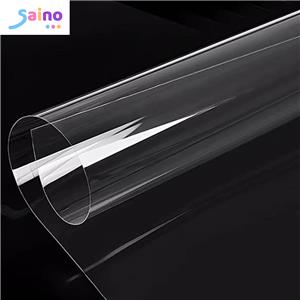

As a non-crystalline copolyester material, PETG film's molecular structure naturally ensures its compatibility with PUR flat lamination. PETG film possesses excellent transparency, high gloss, and good flexibility, while the polyurethane reactive hot melt adhesive used in PUR flat lamination reacts chemically with the PETG film surface after melting upon heating, forming a strong chemical bond.

This bonding method is far superior to traditional physical adsorption, enabling PETG membranes to achieve higher peel strength during PUR flat lamination, effectively avoiding problems such as blistering and delamination later on.

Process Advantages Highlight Material Value

The adaptability of PUR flat lamination to PETG Film is reflected in several dimensions.

First, the PUR flat lamination adhesive forms a cross-linked structure after curing, significantly improving heat resistance, water resistance, and chemical resistance, which synergizes with the excellent weather resistance of the PETG Film itself.

Second, the application temperature of PUR flat lamination is relatively low (approximately 120-140℃), avoiding damage to the PETG membrane performance from high temperatures and maintaining the original high light transmittance and surface smoothness of the PETG Film.

Third, the moderate initial tack of the PUR flat lamination adhesive provides ample operating time for the positioning and adjustment of the PETG Film.

Application Scenarios and Market Feedback

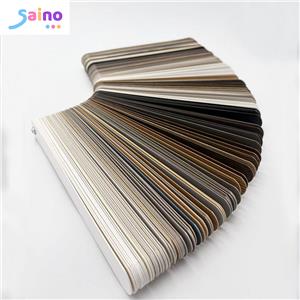

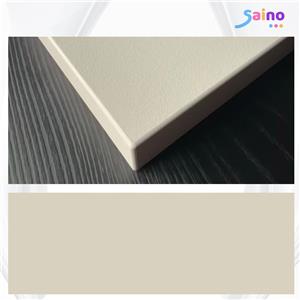

In applications such as furniture edge banding, cabinet doors, and advertising light boxes, PETG film treated with PUR flat lamination results in products with clear edges, smooth surfaces, no bubbles, no orange peel effect, and is less prone to yellowing and peeling over long-term use.

Especially in outdoor applications, the combined UV resistance of PETG film and the weather resistance of PUR flat lamination adhesive extends product lifespan by more than 30%.

Some companies have reported that cabinet doors produced using PETG film in conjunction with PUR flat lamination maintained over 85% of their initial peel strength after 1000 hours of testing in high temperature and humidity environments, far exceeding industry standards.

Technical Challenges and Solutions

Although the combination of PETG film and PUR flat lamination offers many benefits, tight control over process parameters is important when using it in production. The reactivity with the PUR flat lamination adhesive depends on surface tension and polar group content of PETG film making it necessary to adjust temperature, pressure, time by specific grade of PETG films.

In addition, PUR flat lamination adhesives have higher requirements for the wetting properties of PETG films than other materials; therefore a clean and pollution-free film surface is required to obtain good bonding effects. At present, more than some equipment manufacturers have built special PUR flat lamination production line for PETG film in the market, with on-line plasma treatment and corona treatment function to increase the surface activity of PETG film so as to achieve better PUR laminate effect.

Industry Prospects and Trends

Experts in the industry believe that PETG Film + PUR flat lamination is a manifestation of high-performance, environmentally friendly and personalized decorative materials. This material-process combination seems to drive aging PVC materials from more areas of traditional use by growing consumer needs for product quality and tougher environmental regulations.

The subsequent technological development will tend to the optimization process parameters for both; PETG film formulations, PUR flat lamination adhesives and matching respectively. Over the next three years, applications for PETG film in PUR flat lamination sector are reportedly expected to grow at a compound annual growth rate higher than 20%.