Why can PVC film be used in flat lamination, wrapping, and vacuum forming processes?

PVC film (polyvinyl chloride) materials, with their excellent plasticity, weather resistance, and cost advantages, continue to see their application deepen in fields such as architectural decoration, furniture manufacturing, and advertising signage. The three major processes of PVC film—flat lamination, wrapping, and vacuum forming—are developing synergistically, expanding their application boundaries.

Characteristics and Latest Developments of the Three Major Processes

I. Technological Innovation from Flat to Irregular Shapes

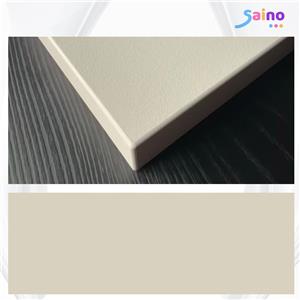

PVC film is used in a wide range of applications, with the most basic being flat lamination (where it is bonded to another substrate surface through adhesives). Flat or simple curved surfaces are the ideal candidates for traditional methods. The most recent technological advancements tend to be reflected in:

Irregular Curved Surface Laminated Flat: By improving adhesive formulations (such as pressure sensitive adhesives, hot melt adhesives and etc), lamination devices can accurately laminate PVC films onto complex curve surface & small radius arching surfaces which will solve jitters or bubbles upon irregular shaped substrates.

Online Hot Press Laminator: it has an infrared heating or hot air circulation system that can run continuously, and the PVC film is laminated at a speed of 10-15 m / min to increase production efficiency by more than 30%.

Waterborne adhesive or UV cured glue solvent-free lamination technology brought VOC emissions to more than 90 percent of PVC film, meet environmental protection requirements.

II. Coating: Making the Jump From Manual to Automatic

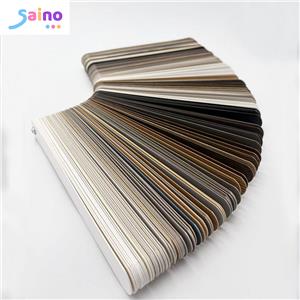

Coating : Coating process is mainly hot-pressing sticking of PVC film on substrate, such as veneer, MDF profile edge or other flat board. Technological upgrades include:

High speed dip coating machine: controlled by servo motor, automatic feeding and cutting for 20~30m/min which is suitable for all kinds of profileष

Hot air coating technology: It softens the PVC film through hot air, and combined with vacuum adsorption or mechanical roller pressure rolls to give a three-dimensional complex profile perfect wrapping (wrap angle can reach 180 ℃ or even full).

Cold glue coating technology: Using cold-glued system, no heating because of this fault and reducing 50% the energy consumption with avoiding negative effects on performance side.

III. From Small Molding to Large Forms- How the Vacuum Forming Process Works?

This method vacuum forming uses heat to soften PVC film and then use the suction of a vacuum pump to make it can be suitable for complex three-dimensional shapes. Key technological breakthroughs include:

High-Precision Adult Toy Thermoforming Machine: With multi-station, multi-temperature zone control and ±1℃ temperature accuracy; the vacuum degree is adjustable to meet the forming requirements of PVCfilms with different thickness embodiments.

Deep film vacuum thermoforming technology: can be equipment and technological reform, 0.5-3.0mm thick PVC protective paste molding; to further expand the product range of applications

2D visual inspection, based on CCD neural camera for normal forming process provides a scrap rate under 3% with respect the PVC film used.

Process synergy and composite applications

It is important to mention that the three processes are not independent of each other, but instead present a trend towards combined development:

Liquid material + wrapping compound technology: first in a flat shape of liquid materials applied to the surface of PVC film substrates, and then wrapped edges treatment process completely achieve overall effect seamless. This method of production is common in the manufacture of furniture, such as a wardrobe or dresser.

Expanded application areas:

Home interior decoration: Flat lamination (fastening PVC film to wall, ceiling line and door face) ; vacuum forming of various shaped irregular shapes such as ceilingsCeiling , decorate moldings etc.

Furniture manufacturing — PVC film wrapping edge sealing in cabinets, wardrobes, office furniture etc., flat lamination or vacuum forming surface decoration.